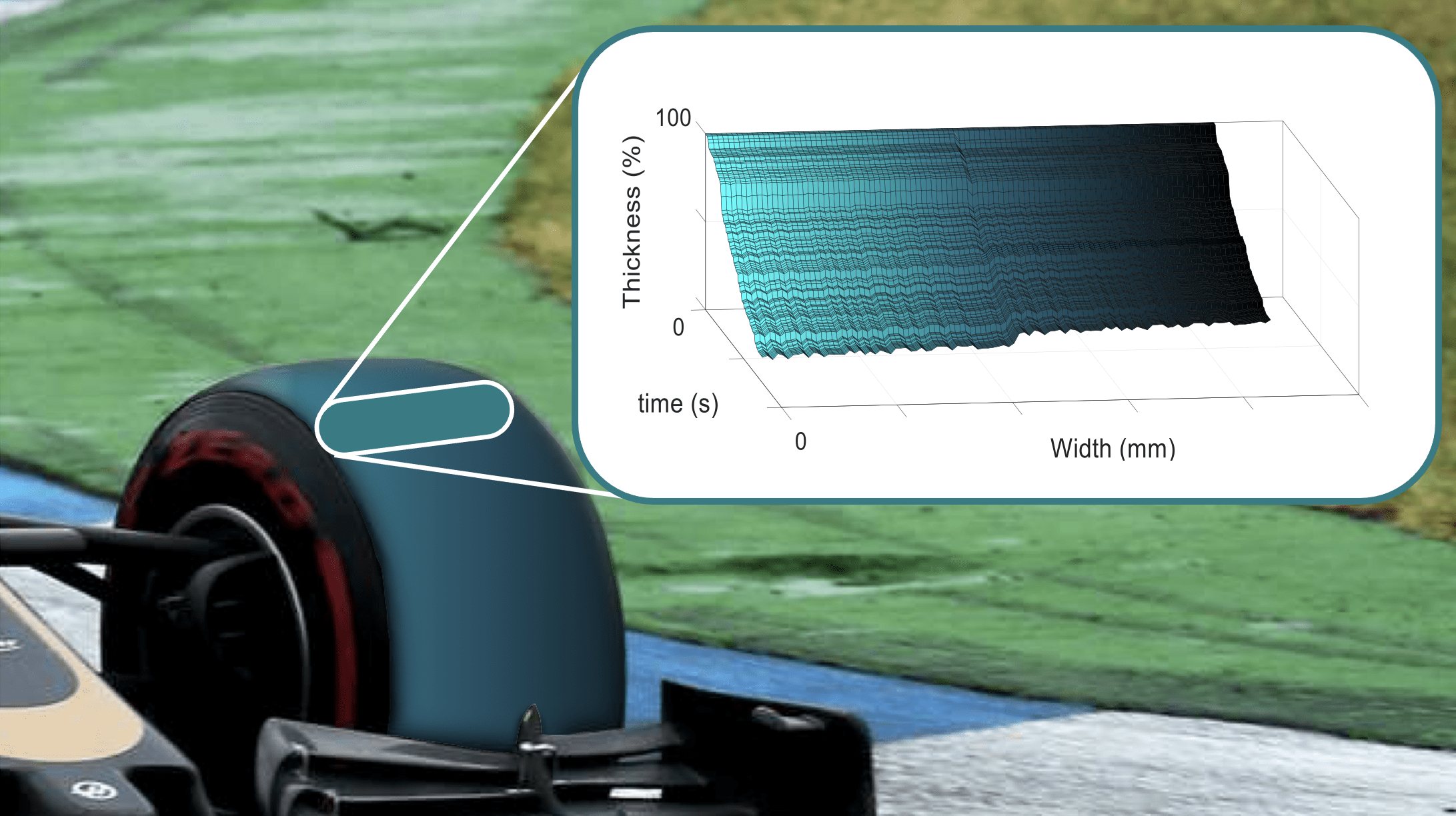

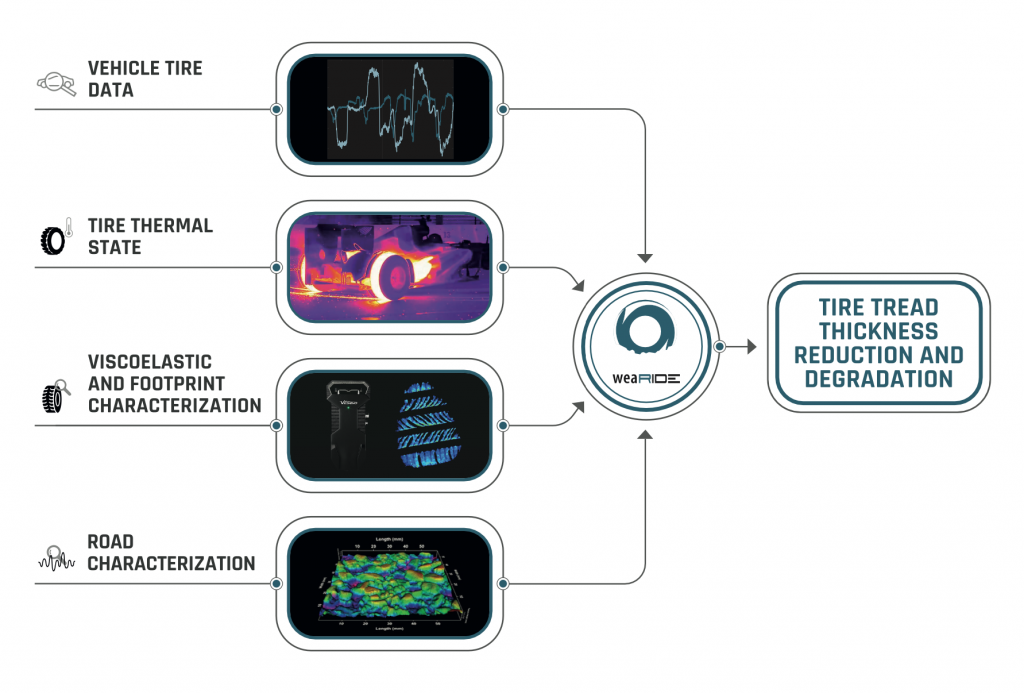

The multiphysical approach proposed by MegaRide has been enriched in the recent past by a wear model, developed to consider tread wear and tire degradation phenomena involved in tire lifecycle and in races. The model takes into account several aspects which concern road and tire compound characterizations, and local thermal phenomena occurring within the contact patch.

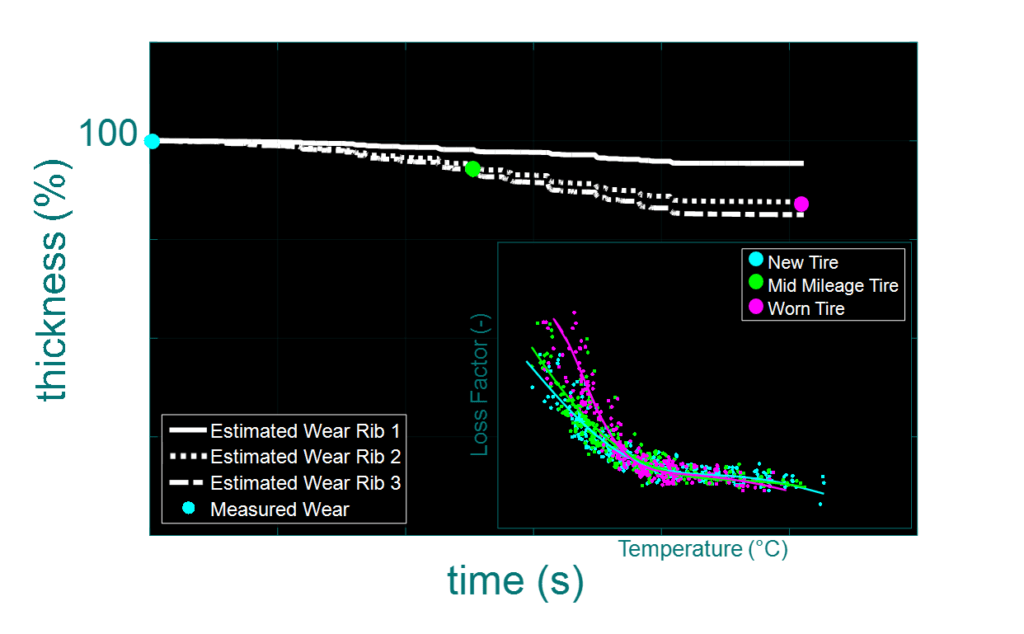

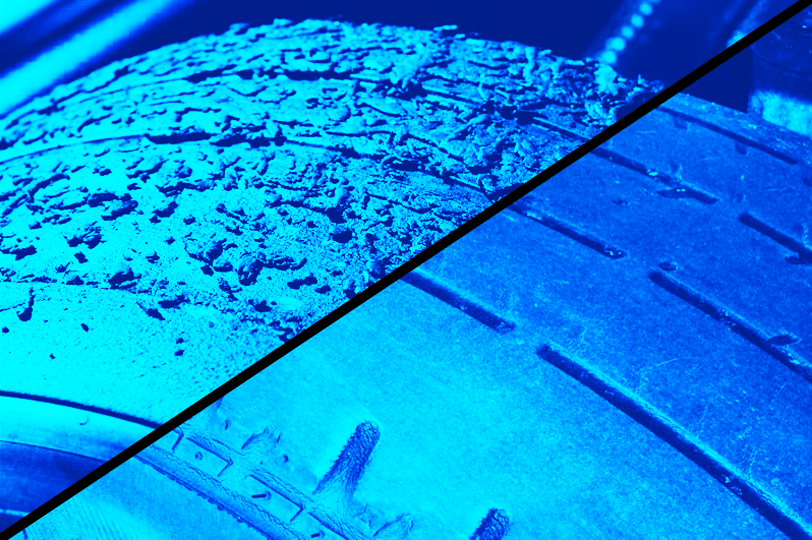

Such a specific modeling allows to discern two important mechanisms: the mechanical abrasion of the compound due to the interaction with the road asperities (wear is proportional to the work done by abrasive friction forces arising at the contact interface) and the chemical degradation of the rubber linked to the thermal fatigue which induces the continuation of the vulcanization process and leads to both the gradual hardening of the compound and the reduction in peak friction capability.

With the aim to let weaRIDE users being able to autonomously parameterize and manage the tire digitalization, a specifically developed tool, called RIDEtool, is provided to the customers

The wear model dependencies can be summarized as follows:

- forces, sliding velocities and rotation frequencies, to evaluate friction power contribution, available within telemetry datasets

- tire temperatures and pressure evaluated employing thermoRIDE thermal model, useful to take into account of the local temperature and pressure distributions

- compound storage modulus, which characterizes the compound viscoelastic behavior and can be available thanks to specific non-destructive test performed with VESevo instrumentation

- contact patches data, useful to take into account of the local stress distribution variation due to different vertical load, camber angle and inflation pressure conditions

- road roughness profile, available from proper measurements and processed analyzing the asphalt power spectral density, reaching an evaluation of macro and micro texture and of the corresponding adhesive and hysteretic friction contributions