A few months after its debut, the device that reveals the secrets of racing tires to obtain maximum performance and safety, is becoming a permanent presence on all competition fields.

Naples 16 July 2021 – From Formula 1 to Formula E, from WRC to MotoGP: VESevo, the exclusive system developed by the Vehicle Dynamics group of the Federico II University of Naples in collaboration with the academic spin-off ‘MegaRide – Applied Vehicle Research’, is becoming more and more a reference point for the teams of all the main motorsport competitions.

VESevo has been adopted by 5 of the 10 Formula 1 teams, 4 Formula E teams, 2 MotoGP teams and lately by the majority of the teams in the WRC.

VESevo, from the Latin name of the iconic volcano, symbol of the Neapolitan territory, is the result of the research activities of the engineers from Federico II University and MegaRide who jointly aimed at a specific initial objective: to know the characteristics of the treads of “racing” tires, without having to remove samples for the analisys and making tires unusable. The type of information provided to motorsport partners makes it possible to predict the behavior of the tire and of the entire vehicle, in variable operating and progressive wear condition to which they are subjected during the race. The technology has progressively found use in large market industrial sectors in order to provide a non-destructive characterization of industrial products, totally or partially composed of polymers, for a rapid and in-situ control of their performance.

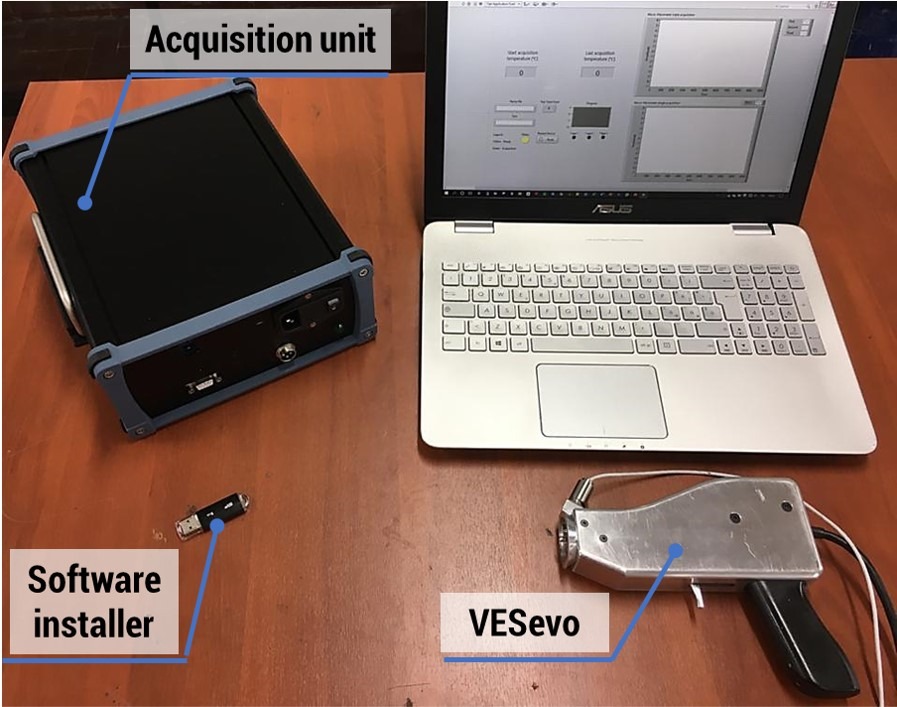

The system consists of a sort of gun whose tip is applied to the tread for information detection, a transponder for connection to the PC and software for data analysis.

What the gun does is help collect information on the tyre tread to understand how it has reacted and behaved while running out on track. Using a unique post-processing algorithm, the software allows its user to fully understand the physical properties of the tyre: offering better analysis of inner temperatures, the stiffness of the compound, the wear of the treat and its damping properties. These can all be mapped out on graphs (below) and then used as a tool to better understand what impact tyre temperature and track surface is having on the performance and durability of the rubber. This information can be crucial for offering added insight into the behaviour of a certain tyre compound, which can then help teams better predict how to get the most out of the rubber.

The adoption of the system meant for the teams a deeper understanding of the characteristics of each tire and completed the information provided by the supplier. This understanding increases the chances of optimizing the use of tires, obtaining significant benefits both in terms of performance and safety, not only of the tires themselves but of the whole vehicle. A competitive advantage that no team wants to deprive in the ever-open challenge for maximizing results and minimizing costs.