Vehicle and tire makers are always focused on finding innovative ways to improve safety. An interesting application of our products in this regard is the possibility to study the influence of one or more components on tire wear, by exploiting the weaRIDE module.

weaRIDE is a wear tire model able to provide real-time tire compound thickness degradation depending on tire working conditions and its interaction with the external environment.

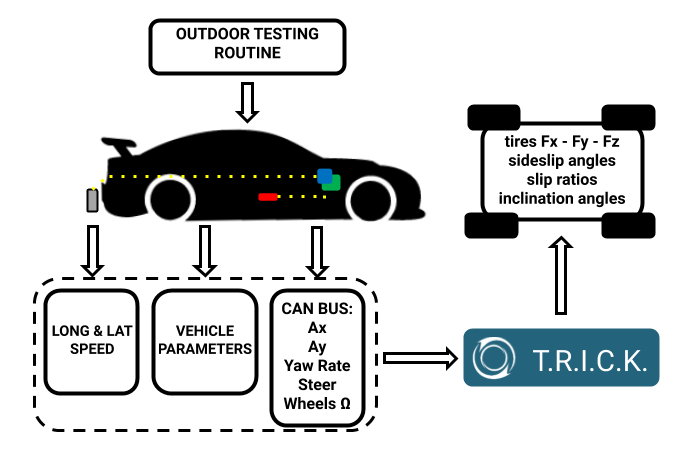

With the employment of TRICK tool, outdoor tests can be used to get information on tire-road interaction, needed for the tire wear model to work, by using different vehicle setups or subsystems design, whose impact on wear is to be analyzed. weaRIDE can be then exploited to evaluate tire wear for each of these configurations, allowing to make considerations on the components used during the tests.

An example is the possibility to test different suspension systems with a professional driver on a racing track and then studying their influence on tire wear through offline simulations with weaRIDE module or by doing the same during an initial design phase in simulator environments with the driver in the loop.

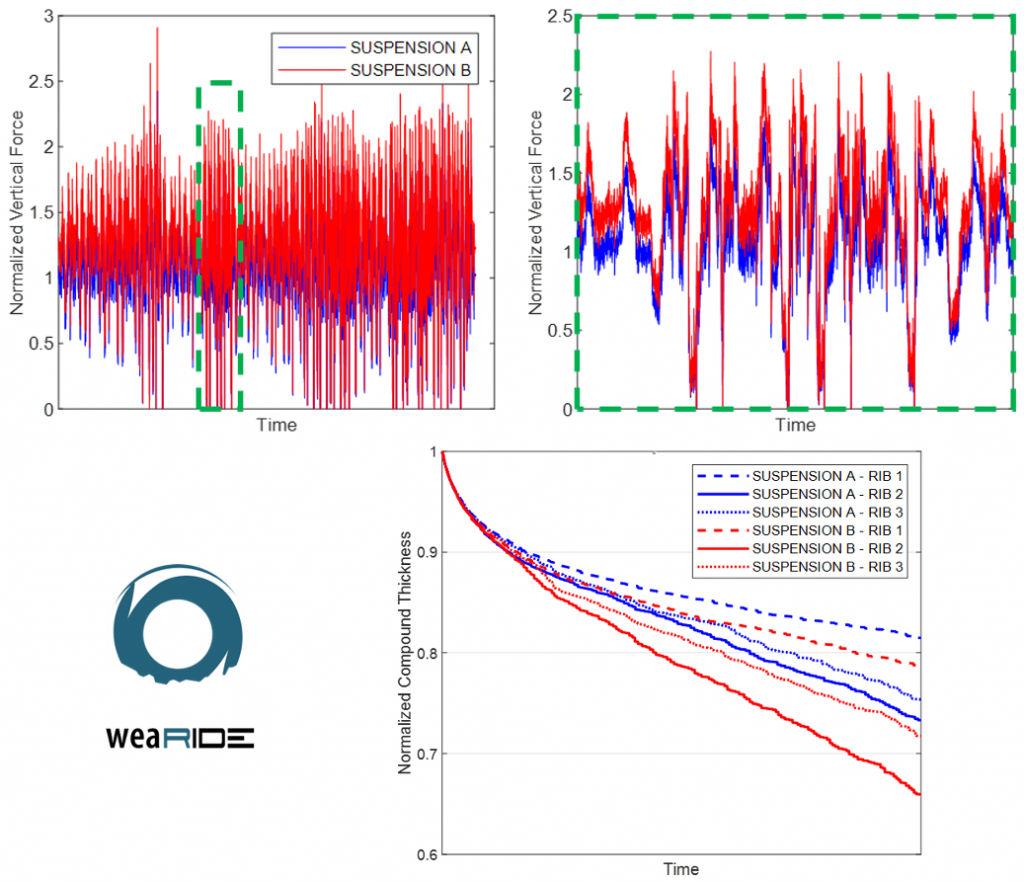

The design of a suspension system highly affects tire wear and thus vehicle safety. A higher spring stiffness for example improves handling by reducing body roll but can lead to increased tire wear due to higher vertical load, especially on rough roads (e.g. SUSPENSION B in the image below). The damping coefficient can be even more important. A lower damping coefficient allows for a smoother ride by letting the suspension move more freely, but excessive oscillations can cause irregular tire wear due to inconsistent contact with the road. A higher damping coefficient on the other hand improves stability, reducing tire bouncing and ensuring even wear, but it might transmit more road shocks, increasing localized stress on the tread. Finally, a lower unsprung mass (lighter wheels and suspension components) allows to maintain better road contact, reducing excessive tire scrubbing.

All these effects are often not taken into account or considered in a final phase of vehicle testing. The weaRIDE module allows to study this influence in offline simulations and real-time environments, such as driving simulators, allowing to reduce suspension system development costs and time.