The handling behavior of a vehicle describes how it responds to driver’s inputs and is strictly connected to performance and safety. It is even more for sport cars, which favor performance over comfort and passenger space.

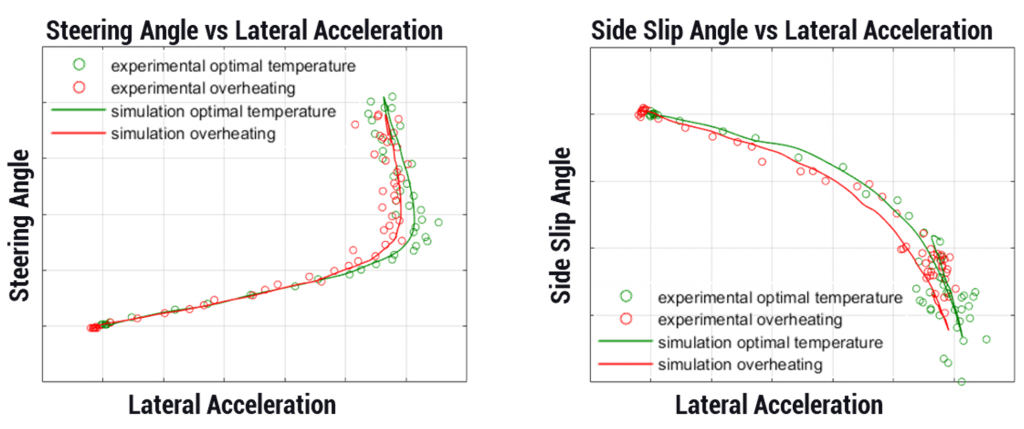

During the design phase of a vehicle and all its sub-components, the handling behavior is usually assessed by performing analysis on vehicle response during lateral maneuvers in steady-state conditions, such as constant radius cornering and slow steer ramp maneuvers. Before validating vehicle behavior performing these maneuvers during experimental test campaigns, it is of common use exploiting the potential of offline simulations and driving simulator sessions. The vehicle model used for development needs to be coupled to a tire model which should reproduce all physical phenomena involved in the interaction between tires and the surrounding environment: this is not the case with conventional tire models. The cornering stiffness is usually considered a constant regarding of the thermal conditions. This of course limits the capability of the simulation to check vehicle performance, safety and lateral stability in critical thermal conditions (very low or high outside temperature). In order to overcome this limit, additional tests (and thus additional costs) will be needed to test vehicle behavior in said conditions.

The combination of thermoRIDE and adheRIDE modules expands vehicle simulations capabilities and can be exploited during vehicle and sub-systems development phase to check performance and safety in critical thermal conditions.

thermoRIDE is a thermodynamic tire model able to provide real-time tire temperature distribution, with particular reference to the internal inaccessible layers, deeply correlated to friction phenomena.

adheRIDE is an evolved version of Pacejka MF model, which considers interlinked multiphysical phenomena that are not considered by the standard formulation, such as thermodynamics effect on tires dynamic behavior.

This multiphysical tire model is able to reproduce tires thermal behavior at different ambient conditions (also critical ones) and even provide tires internal layers temperatures in time, which are needed to replicate tires cornering stiffness at the current thermal conditions. In other words, it is possible to simulate exactly the tests usually performed only in a later phase to check vehicle performance and safety in critical thermal conditions, allowing to reduce time and costs of the development of the vehicle and all its sub-systems.