Motivation

One of the biggest challenges in the automotive field for development engineers and testing technicians is the possibility to obtain reliable tire data to understand their physical behavior. In motorsport, the key is let the tires work in the optimal thermal range (and, first of all, such range has to be determined). In car making, the conjunct tire/vehicle development needs to be fast, to minimize the iterative testing loops, and to objectivize the performance. In tire making, the trade-off among several complex and interconnected features has to be found, guaranteeing safety, optimal friction, durability, low energetic loss and balanced feeling.

The key role tires play in the overall vehicle dynamics, together with the need to achieve results as quickly as possible led car manufacturers to invest more and more time and resources in tire simulation and in the development of physical models and analytical procedures that could describe their working conditions as faithfully as possible and that could be integrated into simulation environments.

At the same time, especially in the motorsport world, where teams are strongly interested in maximizing vehicle, and thus tire, performance, it is necessary to consider the thermodynamic effects in road contact simulations and then within the physical models reproducing interaction phenomena; in fact, the tire exhibits the maximum performance in a fairly narrow range of temperature and pressure, as such two variables mainly affect the maximum achievable grip and the tire stiffness.

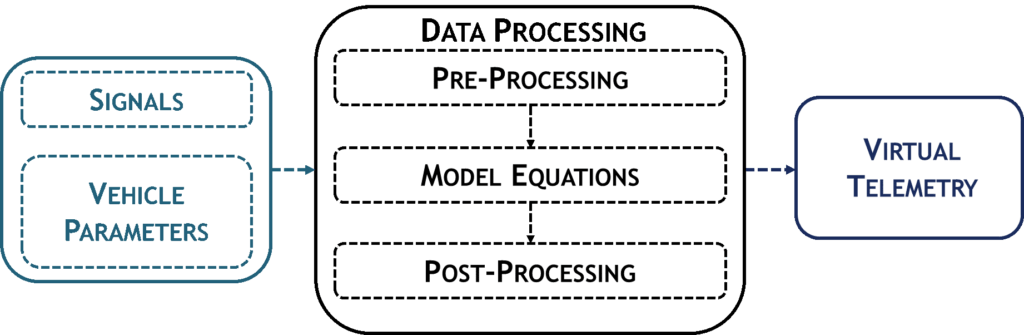

Our technical team has been focused, together with our motorsport partners, on the development of physical-analytical models able to predict tire performance and its thermodynamic behavior. A first tool, called TRICK (acronym for Tire/Road Interaction Characterization and Knowledge), has been developed with the aim to process data acquired from experimental test sessions, estimating tires interaction forces, slip indices and inclination angle. This tool is able to provide a sort of “virtual telemetry” which can be used to feed a thermodynamic model (thermoRIDE), which provides in output the temperature lateral and circumferential distributions, in the different tire layers (tread at three different depths, carcass and inner liner). Through the analysis of the outputs of the above models, fundamental information can be deduced about tire optimal temperature and pressure working range, allowing the definition of a suitable setup to optimize tire and vehicle performance.

From outdoor data to tires characterizations: TRICK tool

TRICK is a development tool to be employed in experimental outdoor activities, able to increase the amount of information that track sessions can provide and to collect data useful to identify the parameters of tire interaction models used in simulations. The main aims for which such methodology has been conceived are:

- tire characterization without bench testing

- objective analysis of test sessions results and performance evaluation

- tire models’ parameters identification

The tool is based on a vehicle model which processes experimental signals acquired from the vehicle CAN bus and from eventual additional instrumentation for the acquisition of the CG speed components.

For a correct employment of TRICK tool, a reliable description of the vehicle is required. The parameters of interest are mainly related to geometric characteristics and to the masses involved when the vehicle is loaded or unloaded (such as the vehicle dry mass, the unloaded radius, the wheelbases, the tracks and the vehicle’s centre of gravity position).

For an efficient data acquisition, it is useful to have dedicated test sessions; the purpose is to investigate tire’s behavior in the widest range of working condition, both from a dynamic and thermal point of view. This is the reason why manoeuvres are planned to be executed by expert drivers able to reach high values of longitudinal and lateral accelerations and to adopt different driving styles to keep tires at the maximum exertion levels.

The model processes the input parameters and signals to calculate the forces basing on dynamic equilibrium and the slip indices on the basis of kinematic congruence equations.

The tool provides a sort of “virtual telemetry”, constituted by the acquired signals and by a number of further channels, including:

- wheels slip indices (slip ratio and slip angle)

- wheels interaction forces (vertical, longitudinal and lateral)

- wheels inclination angles

- run distance

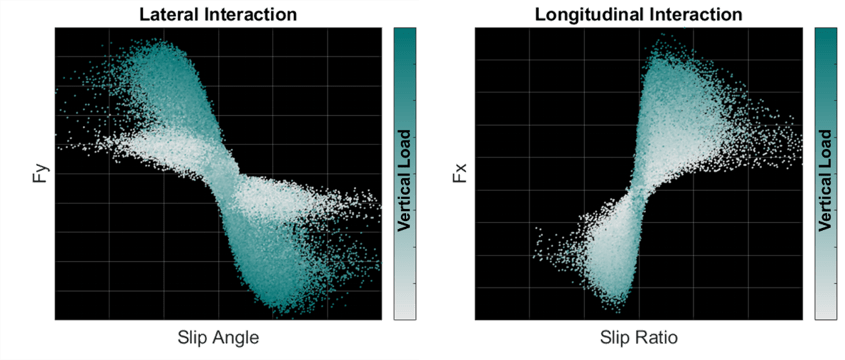

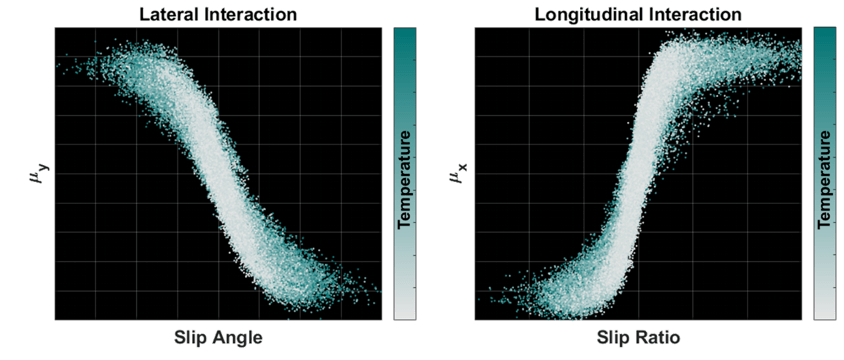

One of the main features of the TRICK procedure is the possibility to get the pure and combined tire/road interaction curves. In the images below an example of lateral and longitudinal interactions is given (please note that, to preserve confidentiality agreements on the data chosen for the case study, all the plots will be shown without axes). Both the characteristics are plotted considering the whole dataset and colored according to the vertical load, as shown in the color bar on the right. The large amount of available points allows to have a good overview of the effects of the main variables which play a crucial role in tire/road contact. For example, forces increase with vertical load; something more will be observed in the following.

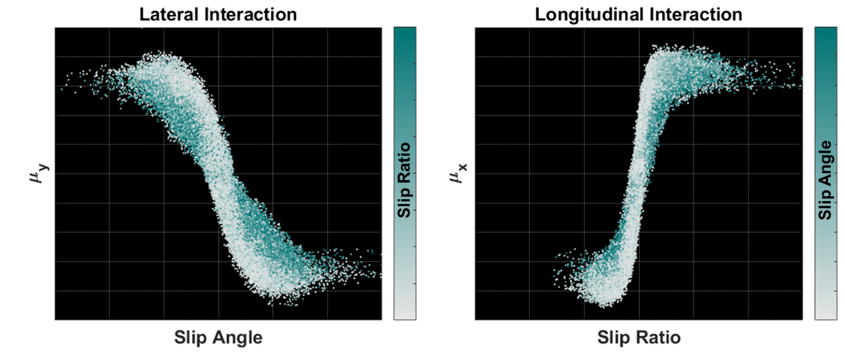

Further interesting information can be obtained plotting the interactions in terms of ratio between tangential and vertical load (defined as grip from now on), and coloring the curves according to the “antagonist” slip indices (slip ratio for lateral, sideslip angle for longitudinal). For example, considering lateral interaction, plotted colored with slip ratio (in percentage) variation, it is possible to highlight the effect of combined interaction on the tire. The grip decreases as the slip ratio increases, as expected; the same can be said for longitudinal interaction.

The described procedure is valid for any type of vehicle and tire. In particular, recently, the application field has been extended to the heavy vehicles, such as truck, bus, agro and OTR. TRICK4TRUCK tool has been thought as a customized version for industrial application of TRICK tool, allowing multi-axles vehicle and tire manufacturers to obtain tire characterizations using their own truck as a moving lab.

thermoRIDE model for tire advanced data analysis and optimal working range investigations

thermoRIDE model is a physical-analytical tire model, developed to analyze and reproduce the phenomena concerning the tire thermal behavior during its interaction with both the external environment and the inner wheel chamber (inner air, rim, brakes, etc.). The thermodynamic evolution of the tire system is described by the diffusion equation of Fourier applied to a three-dimensional domain. The model takes into account of the following physical phenomena:

heat generations due to:

- friction power

- Strain Energy Loss (SEL)

heat exchange with the external environment due to:

- thermal conduction between the tire tread and the road pavement

- thermal convection of the tread surface with external air

- thermal convection of the inner liner surface with the inner air

· heat conduction between the tire nodes due to the temperature gradients

To evaluate the temperatures of the various layers and the inner pressure, it is necessary to feed the thermoRIDE model with a proper “telemetry” containing a series of channels used for the calculation of the heat exchanges. In particular, as mentioned above, the channels essential to allow the model works, provided by TRICK tool in the present case study, are the followings:

- tire forces (longitudinal, lateral and vertical forces)

- tire slips (longitudinal and lateral)

- tire longitudinal velocities

- tire rotation frequencies

- tire inclination angles

- vehicle forward speed

All the information provided by the TRICK virtual telemetry are merged with data related to boundary conditions, such as external air, road and disk temperatures. Moreover, to work properly, the model has to be preliminarily characterized by means of a specific “LAB” version, able to identify thermal (density, conductivity and specific heat) and structural characteristics (SEL characterization and contact patch area measurement at different values of vertical load, inflation pressure and camber angle) with totally non-destructive methodologies.

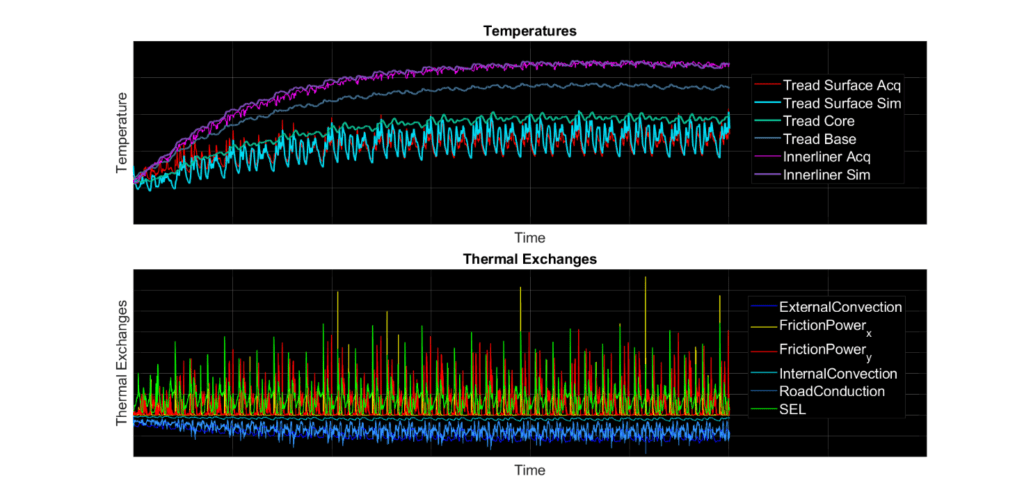

The model gives in output the circumferential and lateral temperature distribution of the different layers in which the tire is discretized along the radial direction:

- tread surface: the most external part in contact with tarmac and external air

- tread core: compound material layer, just below the surface, strictly connected to tire grip

- tread base: the deepest part of the compound layer, linked to tire stiffness

- carcass: the main contributor to the structural behavior of the tire

- inner liner: the layer in contact with the inner air

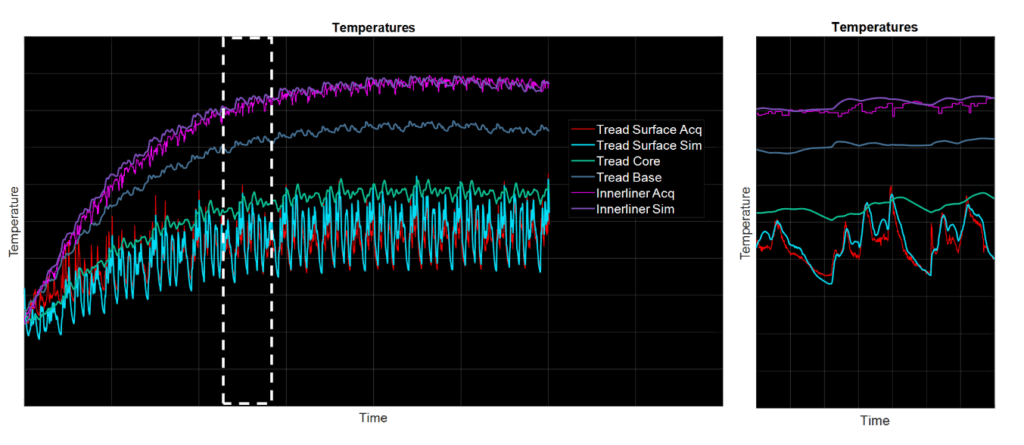

An example of thermoRIDE output is reported in the images below. As written in the legend, the temperatures of the multiple layers are plotted from the most external layer (tread surface) to the most internal one (inner liner). It has to be highlighted that the temperature of the tread core and tread base layers are physically predicted by the model and extremely interesting because not reachable by measurement systems and highly correlated to the global tire stiffness and to the tread hysteretic phenomena. Moreover, the comparison with the acquired experimental data is shown. It is possible to appreciate the various heat exchange rates (in the second subplot), with a specific differentiation between those which contribute to heat up the tire (positive values of the ordinates) and those which cool it (negative values of the ordinates).

The model is validated towards the temperatures that can be acquired through sensors, which are usually mounted to point the tire outer layer (tread surface) and the inner one (inner liner), obtained by means of multiarray IR pyrometers and towards the internal pressure channel acquired by means of a TPMS. Thanks to the discretization along the lateral direction (typically 3 ribs for cars, up to 15 for motorcycle version) the model is able to reproduce the dynamics related to different ribs and the thermal inhomogeneities between them due to steering and different wheel alignment configurations.

The big advantage of thermoRIDE model is that, thanks to the radial discretization, it is possible to evaluate the temperature’s distribution in all the internal layers, which are those which most affect tire performance, especially in terms of grip and stiffness (a specific highlight is shown below).

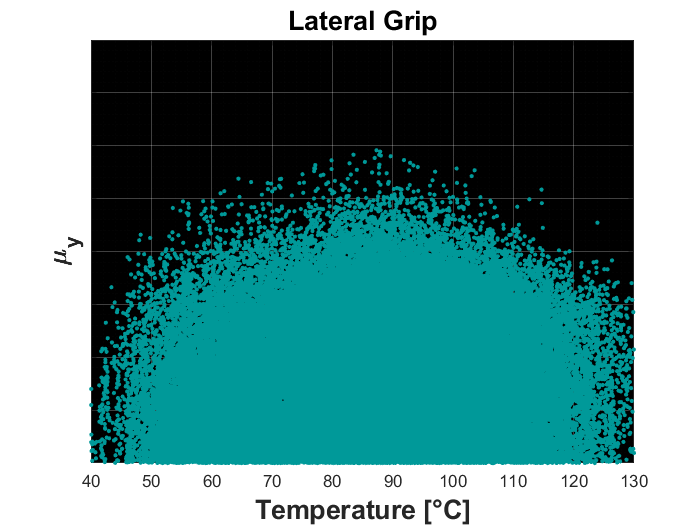

Thanks to the availability of the temperatures of the internal tire layers, it is possible to obtain much more useful correlation, as the ones reported in the figures below, from which the optimal thermal range and the expected bell-shaped curve can be identified. In particular, the temperature adopted in the x-axis is a proper “mix” of the temperatures of different layers, with a significant weight of the tread core one, able to reproduce a clear trend, useful to identify the optimal working range.

The reason for which tread core temperature offers better results can be attributed to the fact that tread surface temperature varies with very fast dynamics, not able to modify in a so short time polymers characteristics in order to have a response on the whole tire frictional behavior. Tread core temperature, instead, is more “reluctant” to fast variations because of its intrinsic inertia and can be easily linked to rubber viscoelastic states.

Similar considerations can be done for the tread base layer, whose temperature is directly linked with tire stiffness and therefore with the variation of the tire’s structural characteristics. In the image above, grip curves are plotted according to tread base temperature variation and, as can be noticed, tire’s stiffnesses decrease as tread base temperature increases. This can strongly influence the global vehicle’s balance, especially for what concerns cornering behavior, since the difference between front and rear axles cornering stiffness characterizes the under/oversteering attitude of a car.

Conclusions

To sum up, models, procedures and methodologies presented are able to describe and analyze different aspects of the phenomena concerning with tire/road interaction, but their cooperation can constitute an even more powerful instrument to extend the comprehension of such complex themes. TRICK and thermoRIDE have been successfully employed together, constituting a useful instrument able to provide tire thermal analysis and to identify the range of temperature in which grip is maximized.

The next step in the tire thermal model development process will be the integration of the wear phenomenon to evaluate the effects of physical abrasion and chemical degradation on the temperature distributions and, consequently, on the attitude to keep the tire working in a proper working range.

Activity carried out by Andrea Sammartino – Modelling & Validation